-

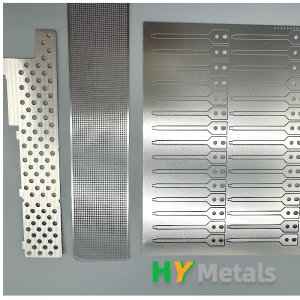

High Quality custom aluminum sheet metal cover with sandblasting and clear anodizing

Dimension: Custom according to design drawings

Tolerance for sheet metal bending: +/- 0.02mm

Material: Copper,brass,stainless steel,aluminum,steel,SPPC,SGCC,SECC,SPHC,cold rold steel,mild steel

Finishe: Sandblasting,anodizing,chemical film,chromate,plating,anodizing,on-demands

QTY: From 1 pcs prototyping to thousands series production

Application:Electronic,medical,aerospace,automation,auto

-

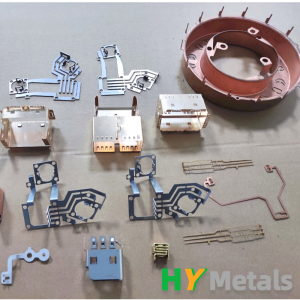

Precision Metal Etching Services from HY Metals: Seamless Part Fixing Solutions

HY Metals has introduced a cutting-edge solution that eliminates the need for traditional joints when etching multiple parts onto sheet metal. This innovative method involves using a special film that is applied to the material before the etching process begins. The film acts as a protective layer, holding everything securely in place during the etching process, eliminating the need for separate joints. As a result, key decorative components can be etched without subsequently removing the connection points, ensuring edges remain smooth and pristine.

-

High Precision and Customization with HY Metals: Leading Custom Sheet Metal Automotive Parts and Busbars

One of the main products manufactured by HY Metals is busbars for automobiles.

Busbars are important components that provide efficient and reliable electrical conductivity in electrical systems.

With advanced machinery and skilled personnel, HY Metals provides tailor-made solutions for custom sheet metal auto parts and busbars. Whether it’s a complex design or specific dimensional requirements, the company’s engineers and technicians have the expertise to develop and produce custom products.

This flexibility allows automakers to build products to their precise specifications, ensuring a perfect fit and optimal performance.

-

HY Metals is a leading sheet metal fabrication services provider with an impressive infrastructure and Professional service

HY Metals is a leading sheet metal fabrication services provider with an impressive infrastructure including four state-of-the-art sheet metal factories. Our facility has over 300 machines capable of handling the full spectrum of sheet metal processing from cutting to finishing.Be it steel, aluminum, brass or any other sheet metal, we have the expertise and machinery to manufacture parts from 1mm to 3200mm with exceptional precision and accuracy.

Our dedicated team of experts and technicians have the knowledge, skills and technical acumen required to deliver outstanding results, no matter how complex the project. From complex prototyping to large-scale production, we are committed to delivering custom solutions that embody the highest precision and attention to detail. By working closely with our clients, we ensure that their unique needs are met with maximum satisfaction and efficiency.

-

Stainless steel sheet metal bracket with black powder coating custom sheet metal parts

Part Name Stainless steel sheet metal brackets with black powder coating Standard or Customized Customized Size 385*75*12mm,2.5mm thickness, according to design drawings Tolerance +/- 0.1mm Material Stainless steel, SUS304 Surface Finishes Powder coating black Application Sheet metal prototype, arm brackets Process Laser cutting-Forming-cutting -Bending -Anodizing -

Custom sheet metal welding and assembly

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. Sheet metal assembly is the process after cutting and bending, sometimes it is after coating process. We usually assemble parts by riveting, welding, pressing fit and tapping to screw them together. Tapping and Riveting Threads are playing an important role in assemblies. There are 3 main methods to get threads: Tapping, riveting, install coils. 1. Tapping threads Tapping is a process ... -

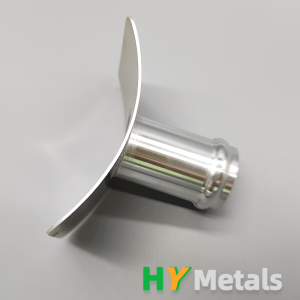

High-quality sheet metal welded component Custom aluminum welding assembly

Part Name High-quality sheet metal welded component Custom aluminum welding assembly Standard or Customized Customized Size 80*40*80mm,according to design drawings Tolerance +/- 0.1mm Material Aluminum tubes and aluminum sheet metal Surface Finishes Clear chromate, chemical film Application Sheet metal prototype, brackets Process Laser cutting-bending-Forming tubs- welding-chromate -

Precision Sheet metal bending and forming process

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. Bending or Forming Sheet metal bending is the most important process in the sheet metal fabrication. It is a process of changing the material angle into a v-shaped or U-shaped, or other angles or shapes. The bending process makes the flat parts to be a formed part with angles, radius, flanges. Usually sheet metal bending includes 2 methods: Bending by Stamping Tooling and Bending by ben... -

High precision metal stamping work include Stamping, Punching and Deep-Drawing

Metal stamping is a process with stamping machines and Toolings for mass production. It is more precision, more faster, more stable, and more cheaper unit price than laser cutting and bending by bending machines. Of course you need to consider the tooling cost first. According to the subdivision, Metal stamping is divided into ordinary Stamping, Deep drawing and NCT punching. Picture1: One corner of HY Metals stamping workshop Metal Stamping has the characteristics of high speed and precisio... -

OEM sheet metal parts with coating and silkscreen

Description Part Name Coated and silk-screened OEM sheet metal parts Standard or Customized Customized sheet metal parts and CNC machined parts Size According to drawings Tolerance According to your requirement, on demand Material Aluminum, steel, stainless steel, brass, copper Surface Finishes Powder coating, plating, anodizing,silkscreen Application For a wide range of industry Process CNC machining, sheet metal fabrication, coating, silkscreen Coated and silk-screened O... -

Stainless steel sheet metal Camera Housing free from bending marks

Sheet metal bending is a common process in manufacturing that involves forming sheet metal into different shapes. While this is a simple process, there are some challenges that must be overcome to achieve the desired results. One of the most important issues is flex marks. These marks appear when the sheet metal is bent, creating visible marks on the surface. In this article, we’ll explore ways to avoid bend marks during sheet metal bending for a nice finish. First, it is important to ... -

Precision metal cutting processes including Laser cutting, Chemical etching and Water Jet

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. The sheet metal materials are usually some metal plates with the size of 1220*2440mm, or metal rolls with a specified width. So according to different custom metal parts, first step will be cut the material to the suited size or cut the whole plate according to the flat pattern. There are 4 main types of cutting methods for sheet metal parts: Laser cutting, water jet, Chemical etching, s...